The FIFO method stands for First In, First Out. It’s a technique used in inventory management, particularly in the food industry. Essentially, it means that the oldest stock or inventory items are used or sold first, ensuring freshness and minimizing waste.

Imagine your pantry or refrigerator as a mini grocery store. When you buy groceries, you should place the newer items behind the older ones. This way, when you restock food, you will use the older items first, reducing the chances of them expiring before use. FIFO helps maintain freshness and prevents food from going bad.

Using the FIFO method to restock food has several benefits. It helps you manage your inventory effectively, reduces food waste, and ensures that you are always using the freshest ingredients. By incorporating FIFO into your food management routine, you can save money and ensure that your meals are of the highest quality.

What Does FIFO Stand For In Food Safety?

In food safety, FIFO stands for the “First In, First Out” method. This approach ensures freshness and reduces waste in food handling. It means using older stock before newer stock in storage and production.

FIFO helps maintain quality by preventing expired or spoiled items. It is a standard practice in restaurants, kitchens, and food storage facilities. By following FIFO, businesses prioritize using older ingredients first, promoting efficiency and safety.

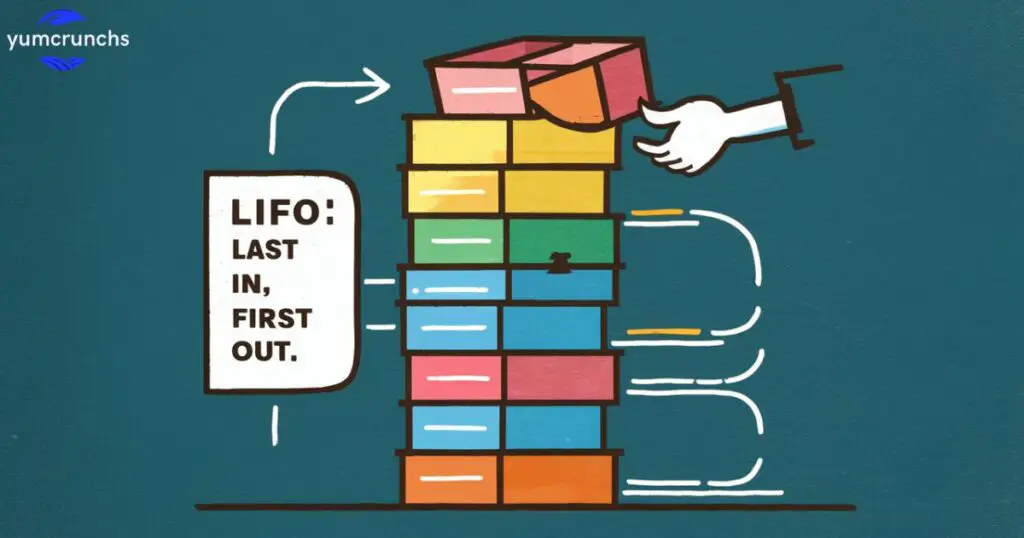

What is the LIFO Method?

The LIFO method, or Last In, First Out, is a way to manage inventory. It involves using the most recently received items first before older ones. Unlike First In, First Out, LIFO prioritizes newer stock over older stock.

While LIFO may offer tax advantages in accounting, it is less common in food safety. Using LIFO in food storage can lead to issues like waste and spoilage. It is crucial to prioritize freshness and quality when handling food items.

What Is FIFO In Cooking?

FIFO in cooking stands for First In, First Out, and is a fundamental principle in food handling. It involves using ingredients in the order they were received or stored, ensuring freshness, and minimizing waste. First In, First Out helps maintain quality by preventing older ingredients from spoiling or expiring.

Restaurants and kitchens commonly apply First In, First Out to their inventory and cooking processes. By prioritizing older ingredients, they reduce the risk of using expired items and maintain food safety standards. Following FIFO ensures that dishes are made with the freshest ingredients available, enhancing flavor and customer satisfaction.

How Do You Use The FIFO Method To Restock Food?

To restock food using the First In, First Out method, first, organize your stock by expiration date. Place newer items behind older ones. When restocking, take from the back, ensuring older products are used first. This prevents food waste and maintains freshness.

Next, regularly check your inventory to rotate stock properly. Train staff on the First In, First Out method to ensure consistency. Label items with expiration dates for easy identification. Keep shelves clean and organized for efficient restocking. This method helps maintain food quality and reduces the risk of spoilage. By following FIFO, you ensure that the oldest items are used first, minimizing waste.

1. Make Sure Sufficient Storage Area

Make sure sufficient storage area is available before starting any project. Lack of space can hinder productivity and cause unnecessary delays. Assess the amount of storage needed based on project requirements and materials.

Allocate designated areas for different items to maintain organization and efficiency. Regularly declutter and remove unused items to free up space for new materials. Utilize storage solutions such as shelves, bins, and cabinets to maximize available space. Properly label storage containers to easily locate items when needed. Implement a system for inventory management to track supplies and prevent shortages. Invest in additional storage solutions if needed to accommodate growing inventory. By ensuring sufficient storage area, you can streamline operations and enhance productivity. Additionally, it’s important to consider Google’s policies, including When Are Food Workers Required to Wear Gloves?, when optimizing your website.

2. Oldest Inventory is Used First

In inventory management, the principle of ‘Oldest Inventory is Used First’ signifies prioritizing older stock. This approach ensures that goods with earlier arrival dates are utilized before newer ones. By following this principle, companies prevent wastage and minimize the risk of obsolescence. It aids in maintaining product freshness and reducing storage costs by avoiding overstocking. Additionally, adhering to this principle helps in managing inventory turnover efficiently, and optimizing cash flow.

Implementing the ‘Oldest Inventory is Used First’ rule streamlines operations and enhances inventory control. It fosters better organization within warehouses and reduces the likelihood of inventory spoilage. Moreover, this principle aligns with FIFO (First In, First Out) accounting methods, ensuring accurate financial reporting. Ultimately, it promotes sustainable practices by reducing waste and maximizing resource utilization.

3. Follow Use-by Dates

Adhering to use-by dates is crucial for maintaining product quality and safety. These dates indicate the recommended time for consuming perishable goods, ensuring freshness. By following use-by dates diligently, consumers minimize the risk of consuming expired or spoiled items. This practice also helps in reducing food waste and promotes healthier consumption habits. Additionally, businesses benefit by upholding customer trust and satisfaction through the delivery of quality products.

For businesses, monitoring and respecting use-by dates is integral to reputation management. It demonstrates a commitment to customer welfare and product integrity. Furthermore, following use-by dates aids in regulatory compliance, ensuring adherence to food safety standards. By prioritizing the consumption of items based on their expiration dates, both consumers and businesses contribute to a more sustainable and efficient supply chain. What is the FIFO Method and How Can it Be Used?

4. Store the Same Food Together

Grouping identical food items streamlines inventory management processes. It facilitates easy access to products and minimizes the risk of stock duplication. By storing similar items together, businesses optimize storage space and reduce clutter within warehouses. Moreover, this practice enhances inventory visibility, enabling efficient monitoring of stock levels. Additionally, grouping food items by category or type simplifies the replenishment process and reduces the chances of errors in order fulfillment.

For consumers, organizing food items in the same category promotes convenience and efficiency during meal preparation. It allows for quick identification of ingredients and helps in reducing food waste by preventing items from getting lost or forgotten. Furthermore, storing similar foods together aids in meal planning and encourages healthier eating habits. Overall, grouping identical food items contributes to a more organized and efficient storage system, benefiting both businesses and consumers alike.

5. Arrange Older Food in Front

Placing older food items at the front of storage shelves ensures they are used first. This method aligns with FIFO (First In, First Out) principles, reducing the risk of spoilage. By prioritizing the consumption of older goods, businesses minimize waste and maintain product freshness. Additionally, organizing items in this manner streamlines inventory management processes, facilitating easier stock rotation and replenishment.

For consumers, arranging older food in front promotes mindful consumption and prevents items from being forgotten. It encourages the utilization of products before their expiration dates, enhancing food safety. Moreover, this practice contributes to more efficient meal planning and reduces the likelihood of purchasing duplicates. Ultimately, prioritizing older food items in front benefits both businesses and consumers by promoting efficient resource utilization and minimizing waste.

6. Maintain FIFO

Following the FIFO (First In, First Out) method ensures the use of older inventory first. This practice reduces the risk of product expiration and waste. By prioritizing the sale or consumption of older items, businesses minimize losses and maintain product freshness. Additionally, adhering to FIFO principles supports accurate inventory tracking and financial reporting.

For consumers, maintaining FIFO aids in selecting fresher products and minimizing food spoilage at home. It encourages mindful consumption habits and prevents the accumulation of expired goods. Moreover, this approach promotes efficient pantry organization and simplifies meal planning. Overall, by prioritizing the use of older inventory, both businesses and consumers benefit from reduced waste and improved product quality.

7. Labels the Rack

Assigning clear labels to racks enhances organization and efficiency in storage facilities. This practice simplifies inventory management by providing easy identification of product categories or sections. By labeling racks, businesses streamline picking and stocking processes, reducing errors and saving time. Moreover, clear labeling facilitates FIFO (First In, First Out) practices, ensuring older items are used first.

For consumers, labeled racks offer convenience and ease of navigation in grocery stores or warehouses. Clear signage enables shoppers to locate desired items quickly, enhancing the shopping experience. Additionally, labeled racks promote better visibility of product options and encourage informed purchasing decisions. Ultimately, labeling racks benefit both businesses and consumers by improving organization, reducing confusion, and facilitating efficient inventory management.

8. Trained Restaurant Staff

Ensuring restaurant staff receive comprehensive training is essential for maintaining high-quality service standards. Proper training equips employees with the necessary skills and knowledge to deliver exceptional dining experiences. By investing in staff training, restaurants can enhance efficiency, consistency, and professionalism in service delivery. Well-trained staff are better equipped to handle various situations, such as handling customer inquiries, managing rush hours, and maintaining food safety standards.

For customers, trained restaurant staff contribute to a positive dining experience by providing attentive and knowledgeable service. Staff members who are well-versed in menu items, dietary restrictions, and service protocols can offer personalized recommendations and address customer needs effectively. Moreover, trained staff contribute to a welcoming and hospitable atmosphere, fostering customer satisfaction and loyalty. Ultimately, ongoing training ensures that restaurant staff remain competent, confident, and capable of delivering memorable dining experiences.

9. Manage and Maintain Food Safety

Effective management and maintenance of food safety standards are paramount in restaurant operations. Establishing stringent protocols and procedures helps prevent foodborne illnesses and ensures compliance with regulatory requirements. Regular training sessions for staff on proper food handling, sanitation, and hygiene practices are essential to uphold food safety standards. Additionally, implementing regular inspections and audits of kitchen facilities and processes helps identify and rectify potential hazards promptly.

For customers, robust food safety measures instill confidence in the restaurant’s commitment to their well-being. Knowing that their meals are prepared and served under safe conditions promotes trust and satisfaction. Transparent communication about food safety practices further reassures customers and strengthens the restaurant’s reputation. Ultimately, prioritizing food safety management not only protects public health but also safeguards the restaurant’s integrity and success.

Benefits of the First In First Out Method

The First In, First Out method offers several advantages in inventory management. Firstly, it minimizes the risk of product spoilage and waste by ensuring that older inventory is used or sold before newer stock. This practice helps businesses maintain product freshness and quality, ultimately reducing financial losses associated with expired goods. Secondly, First In, First Out enhances inventory accuracy and control, making it easier to track stock levels and reorder supplies promptly. This method also aligns with accounting principles, facilitating accurate financial reporting and inventory valuation.

For consumers, First In, First Out ensures that they receive fresher products, promoting satisfaction and trust in the brand. By prioritizing the use of older inventory, businesses reduce the likelihood of selling expired goods, thus enhancing customer safety. Additionally, First In, First Out minimizes the need for discounting or disposing of outdated products, which can lead to cost savings for both businesses and consumers. Overall, the FIFO method promotes efficiency, reduces waste, and improves customer experience in inventory management and retail operations.

FIFO Checklist Process

- First In, First Out (First In, First Out) Checklist Process ensures inventory rotation.

- It verifies the correct labeling of products with arrival dates.

- The process includes regular checks for expired items.

- It confirms adherence to First In, First Out principles in stock handling.

- FIFO Checklist Process aids in maintaining product freshness.

- It involves training staff on First In, First Out procedures.

- Regular audits ensure compliance with FIFO guidelines.

- It helps prevent product wastage and spoilage.

- The checklist process enhances inventory accuracy and control.

- Implementing FIFO Checklist Process supports efficient inventory management.

Where Can I Apply the FIFO and LIFO Method?

| Application | FIFO (First In, First Out) | LIFO (Last In, First Out) |

| Inventory Management | ✔️ FIFO ensures older inventory is used first. | ✔️ LIFO values recently acquired goods. |

| Cost of Goods Sold (COGS) | ✔️ FIFO assumes older, cheaper inventory is sold first. | ✔️ LIFO assumes newer, more expensive inventory is sold first. |

| Financial Reporting | ✔️ The LIFO method may lead to higher COGS during inflation. | ✔️ FIFO can impact cost-basis calculations. |

| Tax Implications | ✔️ FIFO can result in lower taxable income. | ✔️ LIFO may provide tax advantages during inflation. |

| Manufacturing | ✔️ FIFO can be used in assembly lines for materials usage. | ✔️ LIFO can be applied in production to value raw materials. |

| Retail Operations | ✔️ FIFO ensures fresher products are sold first. | ✔️ LIFO may lead to higher ending inventory values. |

| Pricing Strategies | ✔️ FIFO may influence pricing for perishable goods. | ✔️ LIFO may affect pricing during inflationary periods. |

| Supply Chain Management | ✔️ FIFO can optimize inventory turnover. | ✔️ LIFO may be used to reduce taxes on inventory. |

| Investment Analysis | ✔️ FIFO can impact cost basis calculations. | ✔️ LIFO may be preferred for certain investment strategies. |

Comparison of LIFO and FIFO

LIFO (Last In, First Out) and FIFO (First In, First Out) are two common inventory valuation methods. LIFO assumes that the last items purchased are the first to be sold, while FIFO assumes that the oldest items are sold first. LIFO can result in lower taxes due to its tendency to assign higher costs to goods sold. FIFO, on the other hand, often leads to higher reported profits during periods of rising prices.

In terms of cash flow, LIFO typically results in lower cash flows due to higher costs of goods sold. Conversely, FIFO generally leads to higher cash flows because lower costs of goods sold are recorded. LIFO may better match current costs with current revenues, reflecting the actual cost of replacing inventory. However, FIFO may provide a better reflection of the physical flow of goods in certain industries. Both methods have their advantages and disadvantages, and the choice between them depends on factors such as tax implications, industry norms, and financial reporting objectives.

Frequently Asked Questions

How does the FIFO method ensure efficient food restocking?

The FIFO (First In, First Out) method ensures that older food items are used or sold first, reducing the risk of spoilage and maintaining freshness.

What steps are involved in implementing the FIFO method for food restocking?

Implementing the FIFO method involves organizing food items based on their expiration dates, rotating stock so that newer items are placed behind older ones, and regularly checking inventory to ensure compliance.

Why is the FIFO method preferred in food restocking processes?

The FIFO method is preferred because it helps minimize waste by ensuring that food items are used before they expire, maintains quality and freshness, and enhances overall efficiency in inventory management.

Conclusion

In applying the FIFO method to restock food, we ensure that freshness prevails and waste diminishes. By adhering to this strategy, older items are prioritized for use, promoting efficiency and maintaining quality throughout the restocking process. This approach involves meticulous organization, with items arranged based on their expiration dates, and regular inventory checks to sustain compliance.

As we delve into the intricacies of the FIFO method, we uncover its significance in minimizing food waste and upholding standards of excellence. By embracing this practice, we embark on a journey of streamlined inventory management, where each item finds its place in a harmonious flow of replenishment. So, as we contemplate our pantry’s arrangement, let us ponder: How might the FIFO method transform our approach to restocking, ensuring not just efficiency, but also a commitment to freshness and quality?

Daniel, a seasoned author with 8 years of expertise in SEO, brings a delectable blend of culinary flair and digital finesse to the food niche on his website.